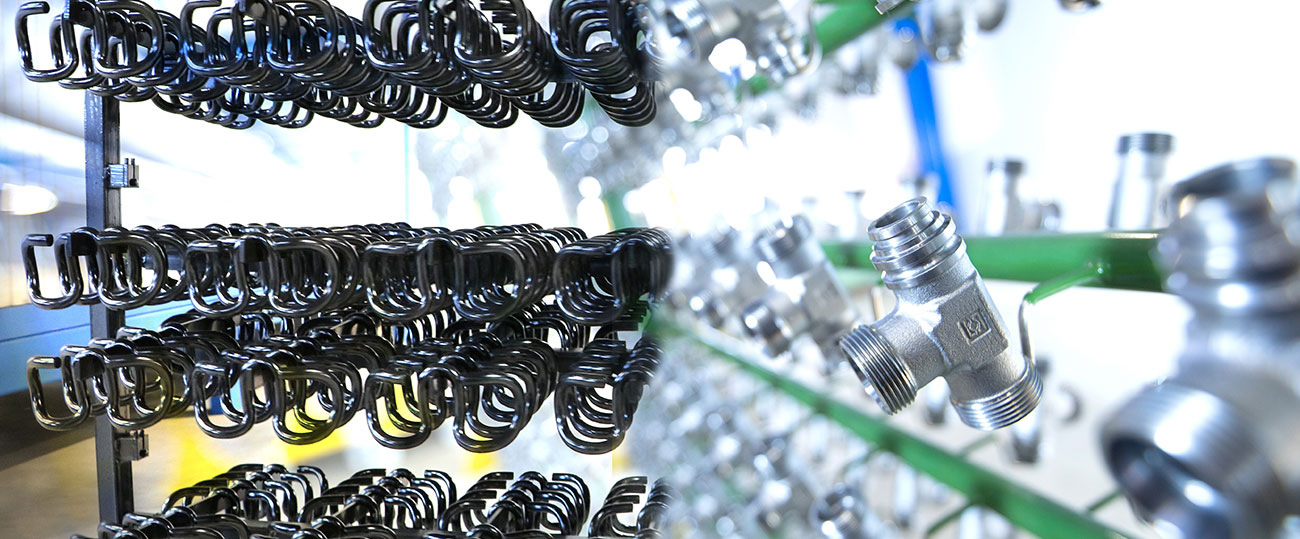

Duplex Systems

- for best long-term protection

The combination of CDC in connection with zinc-alloys forms a classical coating or duplex system. Duplex systems offer the best corrosion protection possible in combination with pitch-black optical characteristics. A resistant, abrasion-proof zinc-nickel or zinc-iron surface prevents subsurface corrosion. The coated parts show high thermal stability, high ductility and an extremely high corrosion resistance and thus substantially withstand higher stress than single coating systems.

Therefore, duplex systems combine the advantages of electroplated surfaces with the advantages of a CDC-finish and justify for premium class surface technologies. Duplex systems coatings are bendable and ductile in most cases without losing their functional superiority.

DUPLEX SYSTEMS AT ONE GLANCE

| +++ Duplex Systems | ||||

|---|---|---|---|---|

| Layer Thickness | Bonding Surfaces | Layer Thickness | ||

| Coating | Zinc Phosphate | ZnNi/ZnFe | CDC/CDC > 35μm | |

| Zinc alloy + CDC / CDC > 35μm | Zinc-Nickel + CDC | x | 4-12μm | 15-20μm |

| Zinc-Nickel + CDC > 35μm | x | 25-45μm | ||

| Zinc-Nickel + CDC | x | 4-12μm | 15-20μm | |

| Zinc-Nickel + CDC > 35μm | x | 25-45μm | ||

| +++ BASE METALS FOR DUPLEX-SYSTEMS |

|---|

Steel, stainless/alloy steel, Fe-cast material, zinc plated meterial, zinc die casting, aluminium material, brass, other material on inquiry

Special treatment with part-specific processes possible.

Duplex systems combine the advantages of electroplated surfaces with the advantages of a CDC-finish. They offer outstanding long-term protection.

Applied fields of duplex systems:

- automotive and supplier industry, e.g. engine compartment and safety components

- utility vehicles

- electrical industry

- construction machinery

- etc.

MUSCHERT +++ GIERSE OFFERS MORE SURFACE TREATMENT TECHNOLOGIES: