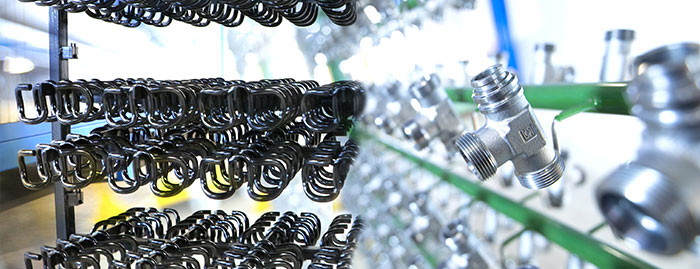

Electroplated Surfaces

- for high and reliable corrosion protection

The process of electroplating applies functional layers of only a few µm on the product base material in order to achieve the designated surface characteristics. The treated parts pass through a variety of process solutions.

The relevant steps during the treatment process are divided in pre-treatment, the actual plating process and the final after-treatment.

Electroplated surfaces come in the form of a stand-alone process or a combination of electroplating with other alloys or surface finishes. A passivation or sealer at the end of the process lead to a higher functional corrosion protection.

ELECTROPLATED SURFACES AT ONE GLANCE:

| +++ ZINC-NICKEL 12-15% ACID | ||||

|---|---|---|---|---|

| passivation Chrome VI-free | Sealer | Prerservation | Rack | Barrel |

| transparent | x | x | x | x |

| +++ ZINC-NICKEL 12-15% ALKALINE | ||||

|---|---|---|---|---|

| passivation Chrome VI-free | Sealer | Preservation | Rack | Barrel |

| transparent | x | x | x | x |

| blue / thick layer passivation | x | x | x | x |

| black | x | x | x | |

| +++ ZINC-FLAKE OPTIONAL IN MEXICO |

|---|

| +++ BASE METALS FOR ELECTROPLATED SURFACES |

|---|

Steel, cast material, zinc-plated material, brass

other material on inquiry

Special treatment with part-specific processes possible.

Sealing with intergrated lubricant possible.

Zinc-Nickel – an optimum of corrosion protection

The electroplated surface finish with Zinc-Nickel offers extremely high corrosion resistance with excellent long-term protection against the exposure to high thermal stress. Internal coatings applied through internal anode technology as well as a final passivation are possible. The after-treatment with selected top coats raise the corrosion and media resistance significantly. Surface finishes with zinc-nickel show an extremely high thermal stability. The process of zinc-nickel acid additionally offers excellent optical characteristics.

Applied fields of zinc-nickel surfaces:

- automotive and supplier industry, e.g. engine compartment, landing gear and underbody areas (turned parts for brake and magnetic systems)

- utility vehicles

- construction machinery

- precision engineering

- offshore facilities

- window construction

- etc.

MUSCHERT +++ GIERSE OFFERS MORE SURFACE TREATMENT TECHNOLOGIES: